timbRfoldR: Making Bending Active Systems Accessible in Planning, Fabrication and Assembly

2020, Okan Basnak, Maximillian Klammer, Gabriel Rihaczek

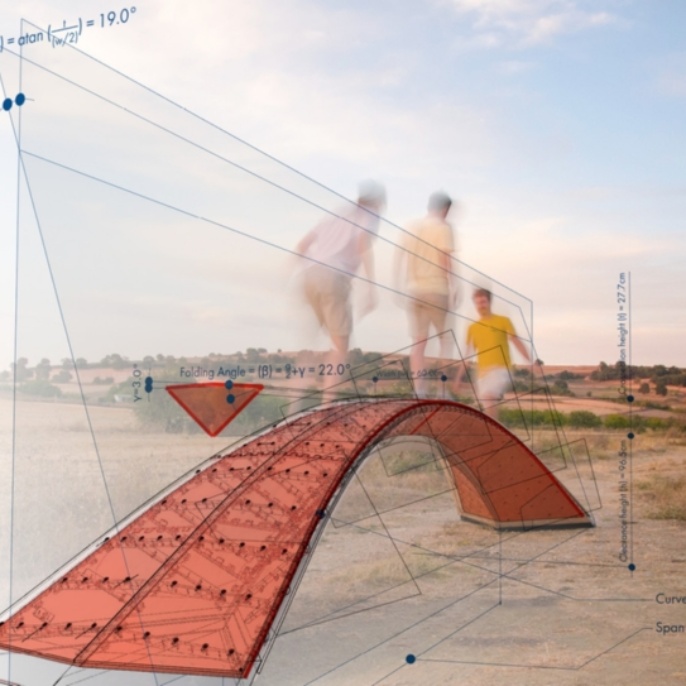

This research explores how the transformation of a structural element can increase the efficiency of construction in fabrication, assembly, transportation, and erection. Curved folding is employed to transform a structural element from a flat to a three-dimensional, bending active and load-bearing state. While bending active structures combine flat production with expressive curvature and thus structural efficiency, curved folding allows to speed up the assembly tremendously by eliminating the need for a laborious assembly of bent plates in three-dimensional space.

On a system level, the kinematic behavior of volumetric curved line folded structures and their design limitations are studied. A structural element typology with closed cross section is developed for efficient material usage by having structural depth. A speculative overview on the variety of spatial component configurations is given. Computational design tools are used to simulate the folding behavior and thereby predict the transformation the structure undergoes.

Further, a kinetic prototype - in the form of a bridge girder - was realized, to prove the feasibility of curved line folding and bending activeness on an architectural scale. A focus lied on the detailed development of bespoke joinery, digital fabrication, assembly, and actuation methods specific to timber plates, which allowed to integrate the production into existing manufacturing infrastructure. Finite element analysis software was employed to evaluate the structural capacity and make design decisions. Additionally, the bending and torsion limitations of the chosen plywood material were taken into account to limit the design space. After the forming process, which in itself is reversible, the structure was locked in the spatial state by its own bistable behavior.

ITECH M.Sc. Thesis Project 2020: timbRfoldR: Making Bending Active Systems Accessible in Planning, Fabrication, and Assembly

Okan Basnak, Maximillian Klammer, Gabriel Rihaczek

Thesis Advisers: Riccardo La Magna, Axel Körner

Thesis Supervisor: Prof. Jan Knippers

Second Supervisor: Prof. Achim Menges

Website: https://www.okagama.eu/