Funding

Bundesministerium für Wirtschaft und Energie, Zentrales Innovationsprogramm Mittelstand, Arbeitsgemeinschaft industrieller Forschungsvereinigungen „Otto von Guericke“ (AiF) Projekt GmbH

ZF4629101TA8

Funding Period

14.01.2019 - 13.01.2021

Description

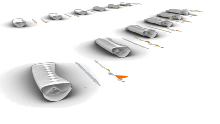

The filament winding process can be used to reliably produce high-quality components from fibre-reinforced polymers (FRP). The process is used economically for the fabrication of series products with high quantities. The spectrum of possible geometries is limited to rotationally symmetrical components. Currently, component sizes ranging from small round tube cross-sections to aircraft fuselages are being realised.

We want to make the classic filament winding process usable for large individual pieces. This enables the production of FRP components for the construction industry. We have a core material at our disposal that is environmentally friendly and reusable. Multi-stage winding cores make it possible to expand the range of shapes to include double-curved and undercut geometries. With these possibilities, the application potential of load-bearing FRP components in the building industry can be drastically increased. The machine-made hybrid elements to be developed from cross laminated timber and FRP will be used to produce components that do not yet exist in this form.

For the industrial production of complex shaped prototypes made of fibre-reinforced polymers, the multi-stage filament winding process is to be investigated on a larger scale for the first time. Starting with the component conception, prototypes are to be produced on a scale relevant to construction on the basis of given geometry and structural requirements. To this end, an industrially applicable process is to be developed with which it will be possible to use multi-part winding core structures to produce geometrically complex, load-bearing components for the construction industry in small quantities. The core material used is to be recovered after production of the component. The following questions will be investigated in the cooperation project:

- What range of shapes can be produced using the filament winding process?

- Which components must the conception/construction process have up to the production of such a component?

- What loads does a winding core made of a sand-binder mixture experience during the winding process?

- How can the sand-binder mixture be produced crack-free to construction-relevant standards?

- How can the sand-binder mixture be made easier to handle (hygroscopy, weight)?

- How can temporary and final core parts be connected in order to realise the multi-stage winding process?

- How can core parts be washed out after the first winding phase without contaminating the laminate?

- How can the wet laminate be placed in a controlled manner in the cavities that have formed?

- How can hybrid components be manufactured from cross laminated timber and FRP components produced by the winding process?

PROJECT TEAM

Nikolas Früh, Prof. Dr.-Ing. Jan Knippers

Partners

Institut für Tragkonstruktionen und konstruktives

Entwerfen, Universität Stuttgart

Nikolas Früh

Keplerstraße 11

70174 Stuttgart

HÄHL GmbH

Dr. Thomas Hähl

Eutinger Str. 29

75249 Kieselbronn

Maus GmbH Technischer Modell- und Formenbau

Mathias Maus

Am Viehweg 9

76229 Karlsruhe

Dienstleister:

Züblin Timber Aichach GmbH

Andreas Amorth

Industriestraße 2

86551 Aichach

Sponsor:

MATERIAL SA

Christian Laval

Rue des Chartreux 11

1000 Brussels

Belgium

The project is an associated project of the Cluster of Excellence IntCDC (more about here)

Nikolas Früh

Dipl.-Ing.Doctoral Candidate