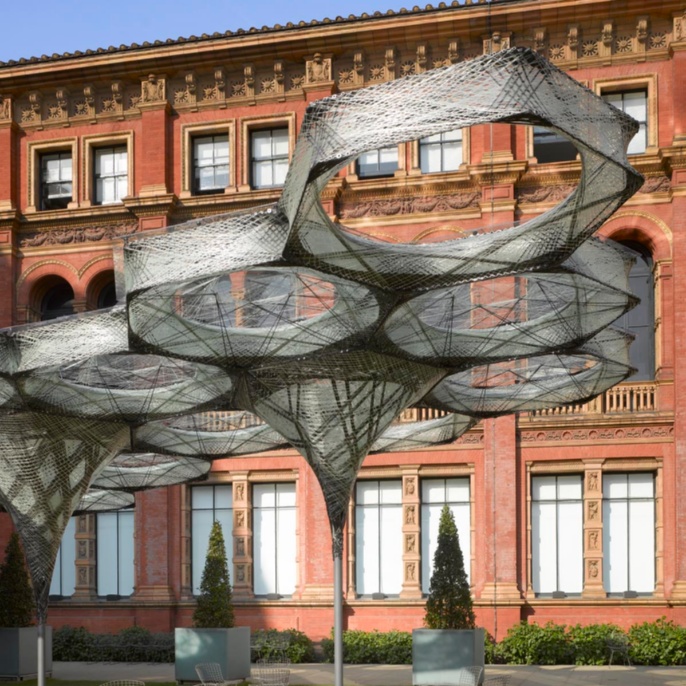

Elytra Filament Pavilion,Victoria and Albert Museum, London, 2016

The Elytra Filament Pavilion celebrates a truly integrative approach to design and engineering. As a centrepiece of the V&A’s Engineering Season it demonstrates how architectural design can unfold from a synergy of structural engineering, environmental engineering and production engineering, resulting in unique spatial and aesthetic qualities. It showcases the profound impact of emerging technologies on our conceptualisation of design, engineering and making, by intensifying the visitors architectural experience of the museum’s central garden. But instead of being merely a static display, the pavilion constitutes a dynamic space and an evolving structure. The cellular canopy grows from an onsite fabrication nucleus, and it does so in response to patterns of inhabitation of the garden over time, driven by real time sensing data. The pavilion’s capacity to be locally produced, to expand and to contract over time provides a vision of future inner city green areas with responsive semi-outdoor spaces that enable a broader spectrum of public activities, and thus extend the use of the scarce resource of public urban ground.

DESIGN EXPLORATION

While allowing for a glimpse of the future, the pavilion also draws inspiration from a striking architecture of the past: the Victorian Greenhouses. They embody the profound impact that the first industrial revolution had on architecture and showcase the experimental spirit of architects and engineers that embrace the adoption of new modes of making and materials in a truly explorative manner. In a similar way, the installation seeks to forecast how the so-called fourth industrial revolution of robotics and cyber-physical production systems enables the emergence of new structural and material systems. In the Victorian Greenhouse, the convergence of constructional and environmental aspects results in the unique experiential environment of an interior green space. Through a transparent, adaptive and growing canopy the installation aims to extend this precedent towards evolving and adaptive semi-outdoor urban green spaces.

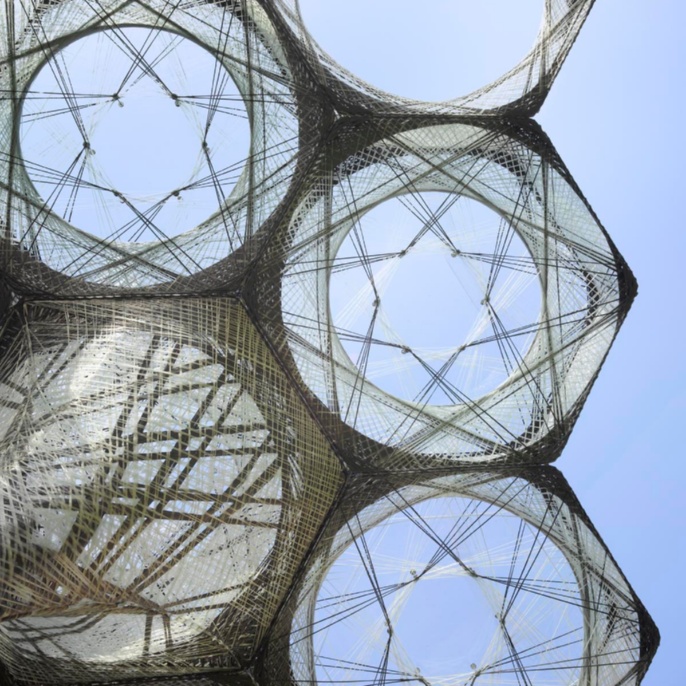

A second design inspiration is the unsurpassed effectiveness and resourcefulness of living nature. Today, with the help of advanced computational design, simulation and fabrication we can tap the vast reservoir of biology and explore the underlying working principles of natural systems in design and engineering. The pavilion is the outcome of four years of research on the integration of architecture, engineering and biomimetic principles. It explores how biological fibre systems can be transferred to architecture. The 200m² pavilion structure is inspired by lightweight construction principles found in nature – the fibrous structures of the forewing shells of flying beetles known as elytra.

ENGINEERING INTEGRATION

Fibre composites are the building systems of nature. Most load-bearing structures in biology are fibrous systems, in which the fibre organisation, directionality and density is finely calibrated with the occurring forces. The resulting high level of morphological differentiation and related resource efficiency is emblematic for natural structures. The biomimetic principles of using “less material” by having “more form” have been investigated for several years by the project team, and they directly influence the conception of the installation’s structure.

The fibrous composite structure of the installation only consists of two basic cells, the canopy cells and the column cells that interface between the inhabitable ground and the canopy, which is also equipped with transparent roof panels. Both cells are made from the same load-bearing fibre material: transparent glass fibres and black carbon fibres. The production itself is an innovative robotic winding process developed by the project team, which in contrast to most other composite fabrication processes does not require any mould, and thus reduces waste to a minimum. To make each cell, a robot winds resin-saturated glass and carbon fibres onto a hexagonal winding tool. In this process, the transparent glass fibres form a spatial scaffold onto which the primarily structural black carbon fibres are applied, as they offer significantly higher stiffness and strength than the glass fibres. Once the robotic fabrication is complete the composite material hardens and the winding tool can be taken out and reused. Despite the similarity in basic make-up, the robotic fabrication process enables an infinite range of morphological permutations of the cells.

Instead of a linear workflow the design, engineering and production of the installation’s fibrous system is based on a continuous feedback loop. As the design, structural analysis and adaptation of each cell is a fully digital process, the machine control code for the robotic fabrication can be directly derived. Each canopy cell is adapted to its specific loading condition through a differentiation of its fibre arrangement, density and orientation, resulting in a very material efficient and light structure, which weighs just 9kg/m².

EVOLVING SPACE

The installation exploits the compactness and universality of robotic fabrication as a model for local manufacturing. While the majority of composite building elements have been prefabricated at ICD’s laboratory in Stuttgart, production continues in the V&A’s garden during specific fabrication events. Here the raw materials – simple, small and lightweight spools of fibre that are pre-impregnated with resin – are used for the onsite production of composite building elements that form additional cells of the canopy structure.

As there is no predetermined final state, the canopy is equipped with fibre optical sensors that allow for the real time sensing of the forces within the structure. This allows monitoring the changes to the structural systems caused by the further growth and adaptation of the canopy, which is driven by anonymous data on how visitors use the canopy space captured by thermal imaging sensors and interpreted in conjunction with the measurement of environmental parameters such as temperature, radiation, ambient humidity and wind. The real-time sensing combined with the onsite fabrication renders the canopy a learning system and evolving structure that will grow and reconfigure over the time of the exhibition, based on the behaviour of the garden’s visitors, and their preferred places to walk, stroll, rest or meet.

The canopy constitutes a fibrous tectonic system that is as architecturally expressive as it is structurally efficient. It provides the visitor with a unique spatial experience that transforms and evolves over time. The canopy also represents a live research project, which is most fitting for the history and ambition of the V&A.

DESIGN, ENGINEERING AND FABRICATION TEAM

Achim Menges with Moritz Dörstelmann

ICD – Institute for Computational Design, University of Stuttgart

Achim Menges Architect, Frankfurt

Team also includes: Marshall Prado (fabrication development), Aikaterini Papadimitriou, Niccolo Dambrosio, Roberto Naboni, with support by Dylan Wood, Daniel Reist

Jan Knippers

ITKE – Institute of Building Structures and Structural Design, University of Stuttgart

Knippers Helbig Advanced Engineering, Stuttgart, New York

Team also includes: Valentin Koslowski & James Solly (structure development), Thiemo Fildhuth (structural sensors)

Thomas Auer

Transsolar Climate Engineering, Stuttgart

Building Technology and Climate Responsive Design, TU München

Team also includes: Elmira Reisi, Boris Plotnikov

With the support of:

Michael Preisack, Christian Arias, Pedro Giachini, Andre Kauffman, Thu Nguyen, Nikolaos Xenos, Giulio Brugnaro, Alberto Lago, Yuliya Baranovskaya, Belen Torres

Commission:

Victoria & Albert Museum, London 2016

FUNDING

Victoria & Albert Museum, London

University of Stuttgart

Getty Lab

Kuka Roboter GmbH + Kuka Robotics UK Ltd

SGL Carbon SE

Hexion

Covestro AG

FBGS International NV

Arnold AG

PFEIFER Seil- und Hebetechnik GmbH

Stahlbau Wendeler GmbH + Co. KG

Lange+Ritter GmbH

STILL GmbH

PICTURES

ELYTRA FILAMENT PAVILION, Victoria

& Albert Museum, London

© NAARO

© Roland Halbe