Photographs by ICD/ITKE, University of Stuttgart

Photographs by Roland Halbe

Development Process by ICD/ITKE, University of Stuttgart

Photographs by BUGA Heilbronn GmbH 2019

BUGA FIBRE PAVILION

Bundesgartenschau, Heillbronn, 2019

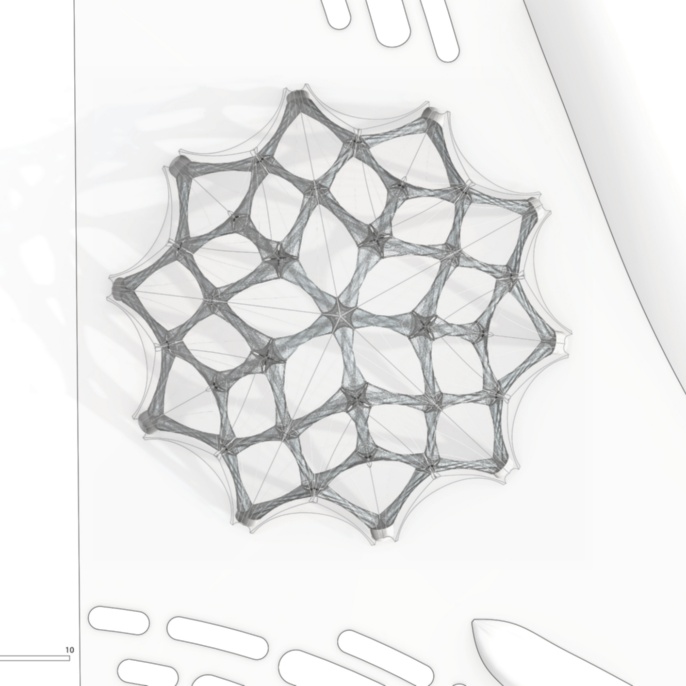

Embedded in the wavelike landscape of the Bundesgartenschau grounds, the BUGA Fibre Pavilion offers visitors an astounding architectural experience and a glimpse of future construction. It builds on many years of biomimetic research in architecture at the Institute for Computational Design and Construction (ICD) and the Institute for Building Structures and Structural Design (ITKE) at the University of Stuttgart.

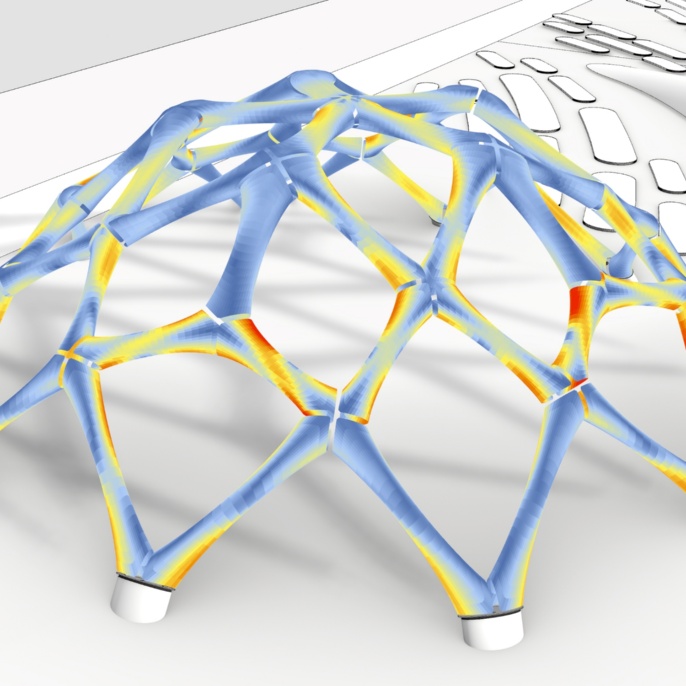

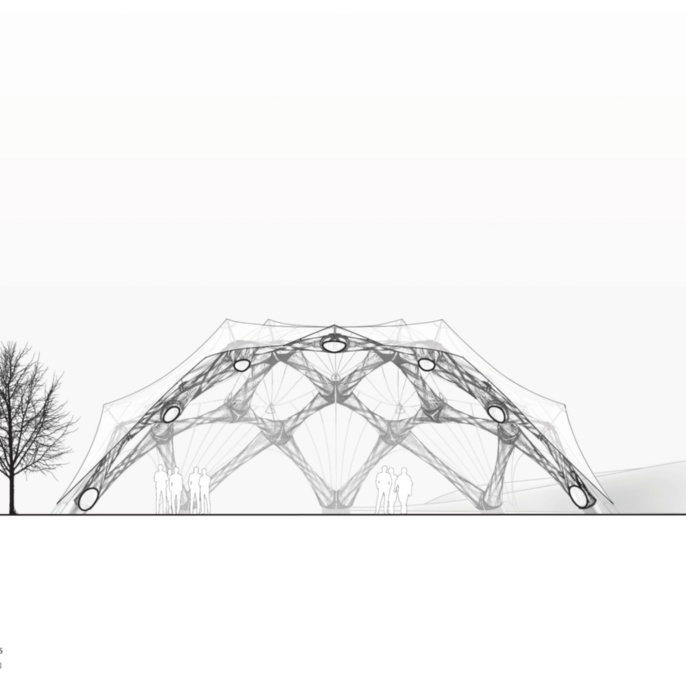

The pavilion demonstrates how combining cutting-edge computational technologies with constructional principles found in nature enables the development of truly novel and genuinely digital building systems. The pavilion’s load-bearing structure is robotically produced from advanced fibre composites only. This globally unique structure is not only highly effective and exceptionally lightweight, but it also provides a distinctive yet authentic architectural expression and an extraordinary spatial experience.

NOVEL COMPOSITE BUILDING SYSTEM INSPIRED BY NATURE

In biology most load-bearing structures are fibre composites. They are made from fibres, as for example cellulose, chitin or collagen, and a matrix material that supports them and maintains their relative position. The astounding performance and unrivalled resource efficiency of biological structures stem from these fibrous systems. Their organization, directionality and density is finely tuned and locally varied in order to ensure that material is only placed where it is needed.

The BUGA Fibre Pavilion aims to transfer this biological principle of load-adapted and thus highly differentiated fibre composite systems into architecture. Manmade composites, such as the glass- or carbon-fibre-reinforced plastics that were used for this building, are ideally suited for such an approach because they share their fundamental characteristics with natural composites.

The project builds on many years of biomimetic research at the Institute for Computational Design and Construction (ICD) and the Institute for Building Structures and Structural Design (ITKE). It shows how an interdisciplinary exploration of biological principles together with the latest computational technologies can lead to a truly novel and genuinely digital fibre composite building system. Only a few years ago, this pavilion would have been impossible to design or build.

INTEGRATIVE COMPUTATIONAL DESIGN AND ROBOTIC FABRICATION

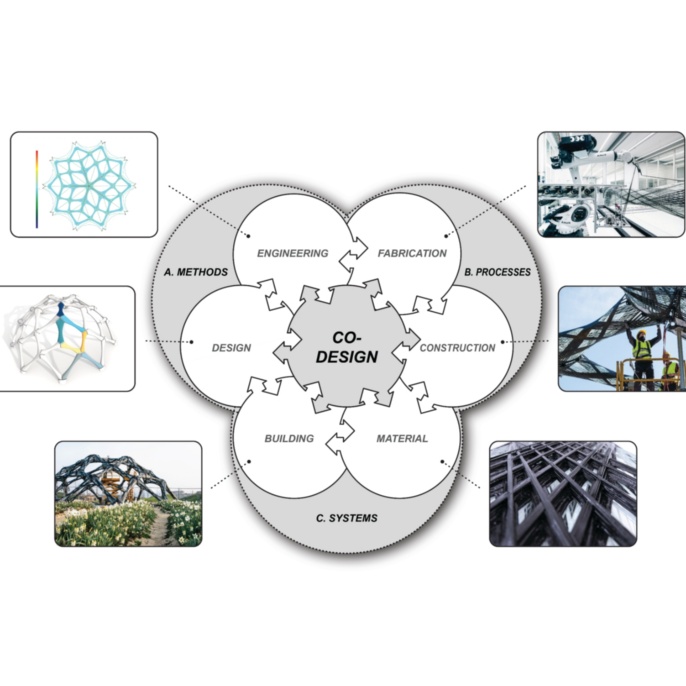

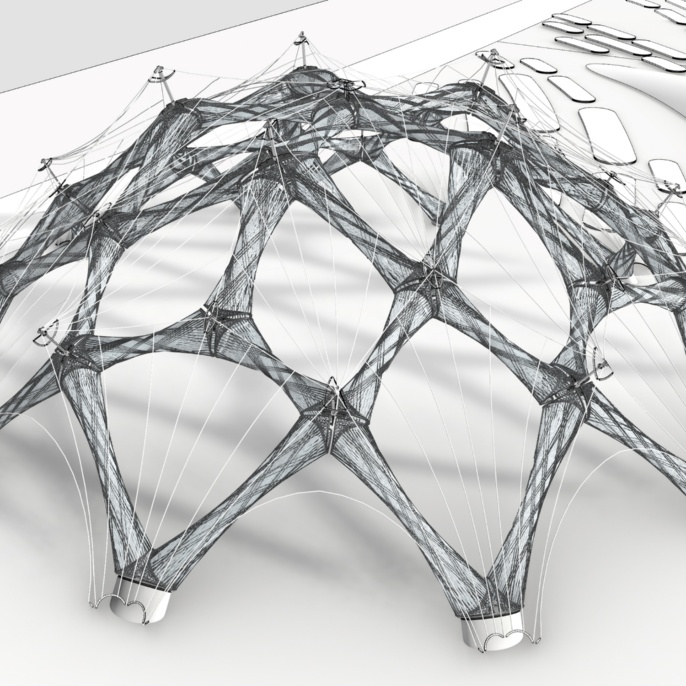

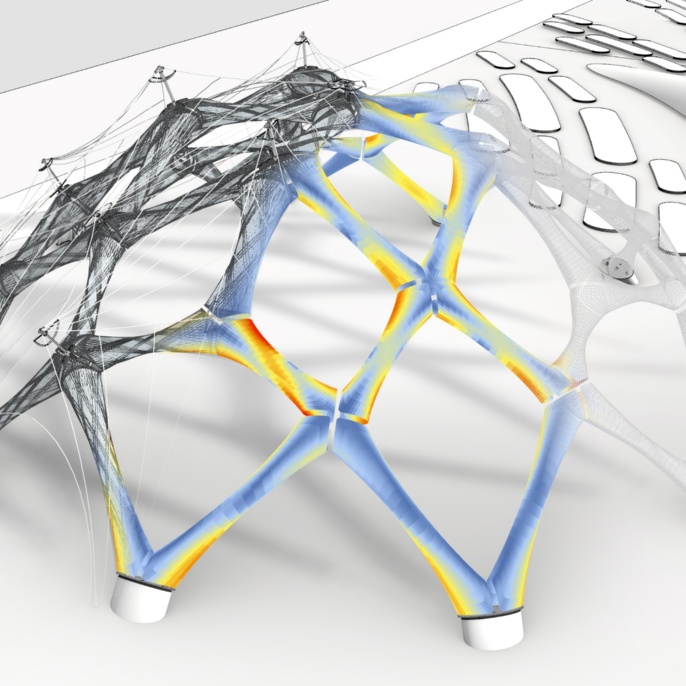

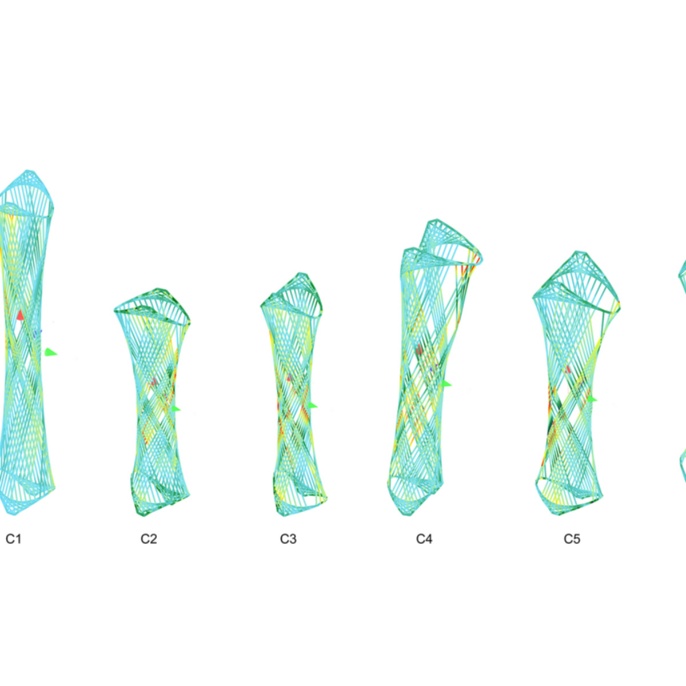

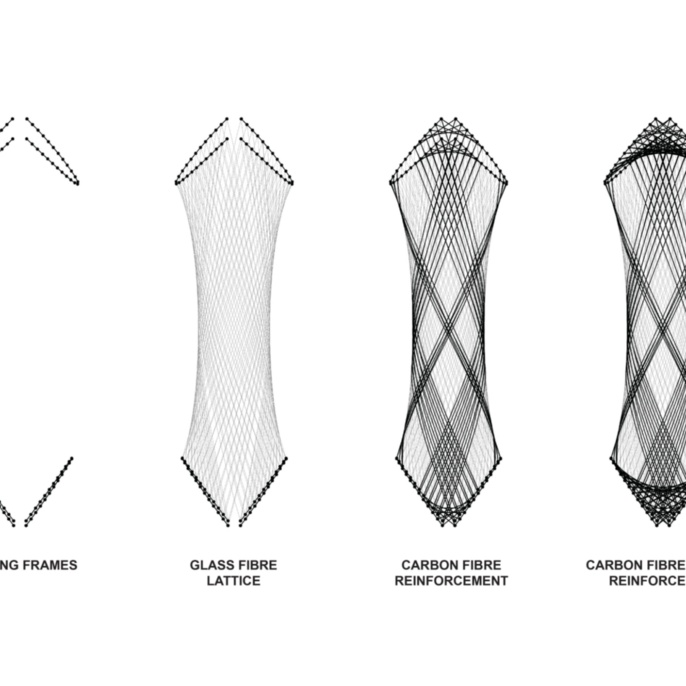

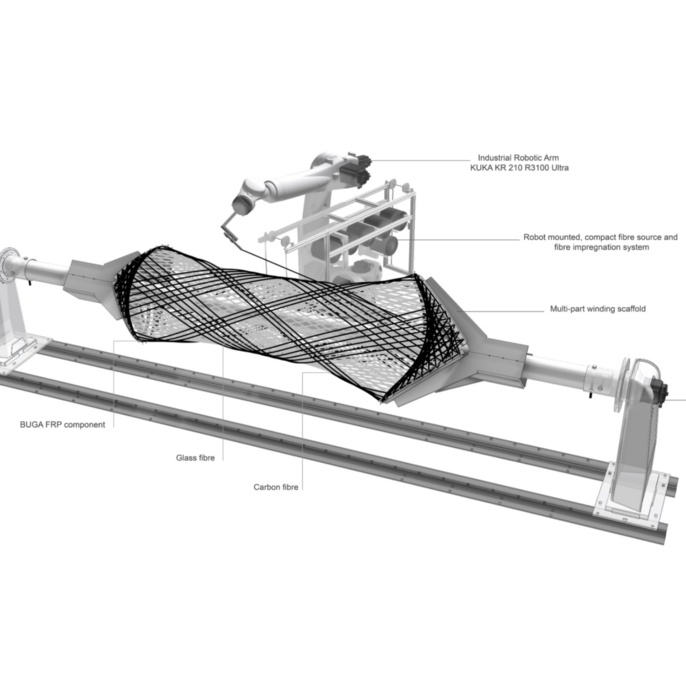

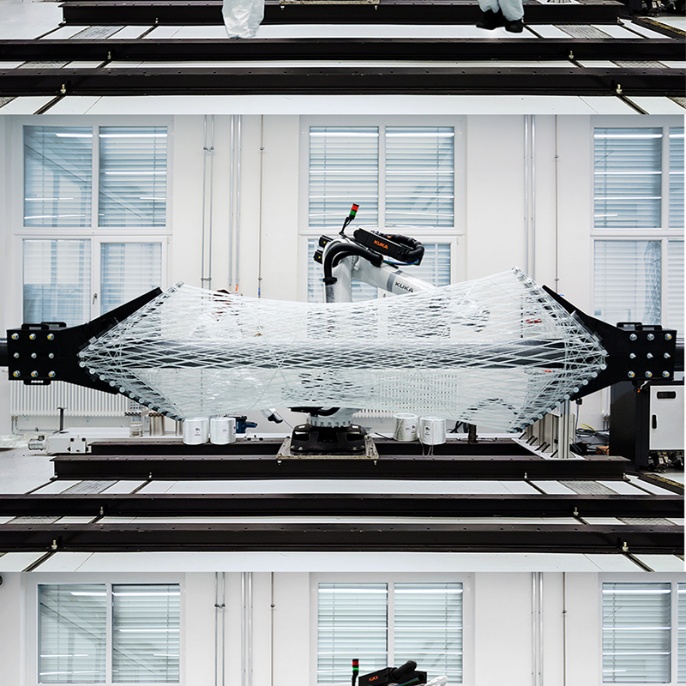

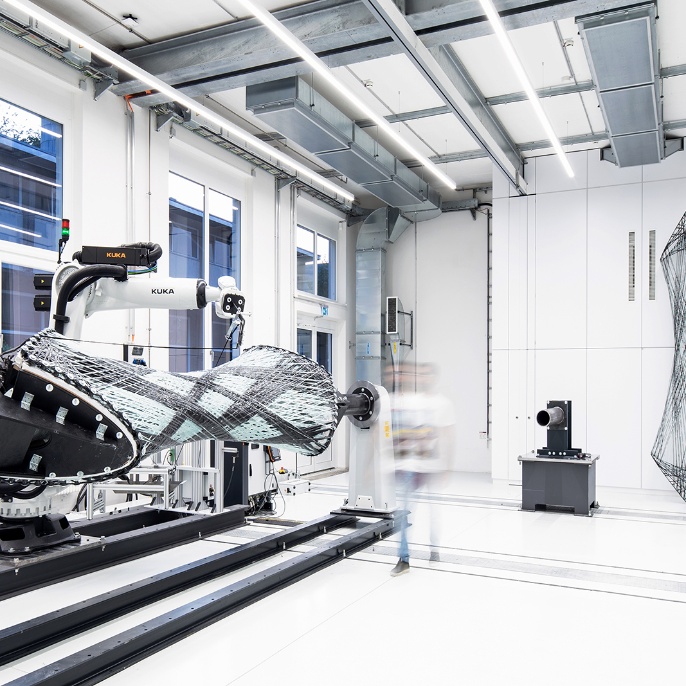

The pavilion is made from more than 150.000 meters of spatially arranged glass- and carbon fibres. They all need to be individually designed and placed, which is very hard to achieve with a typical linear workflow and established production technologies. Thus, it requires a novel co-design approach, where architectural design, structural engineering and robotic fabrication are developed in continuous computational feedback. In this way, the fibre arrangement, density and orientation of each building component can be individually calibrated, structurally tuned and architecturally articulated, while remaining directly producible.

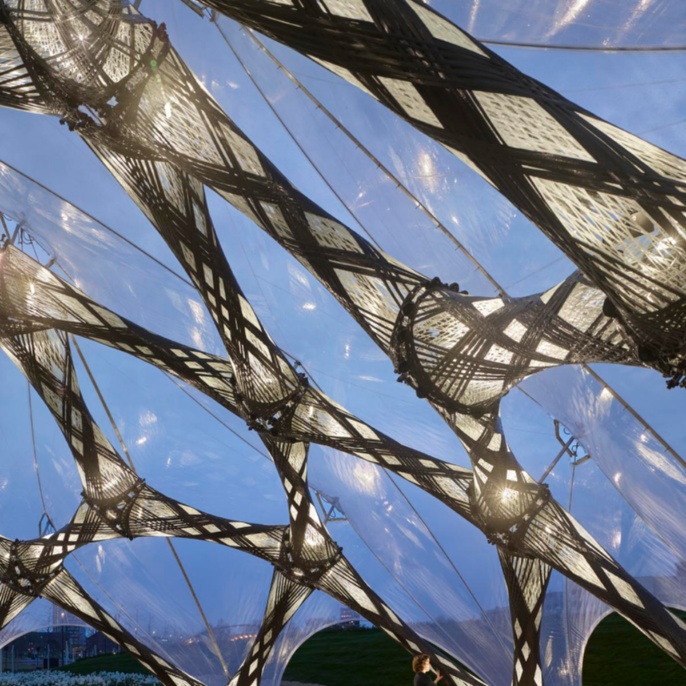

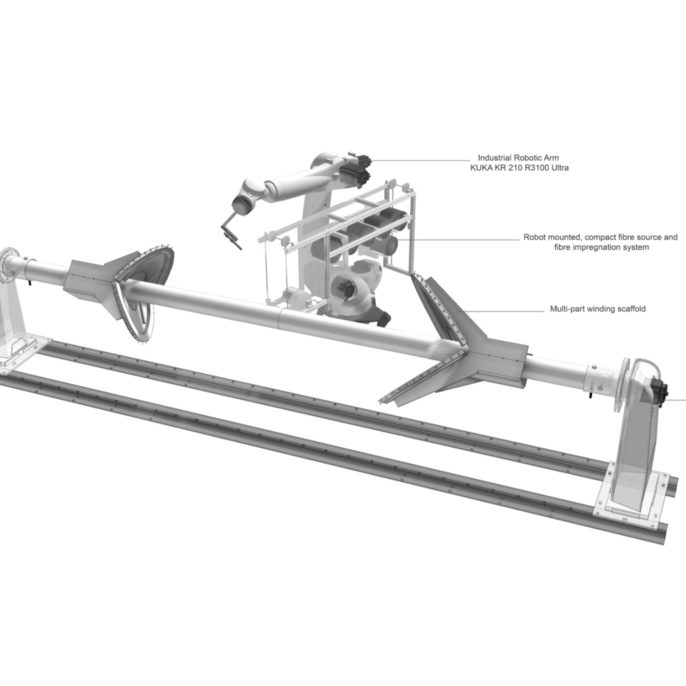

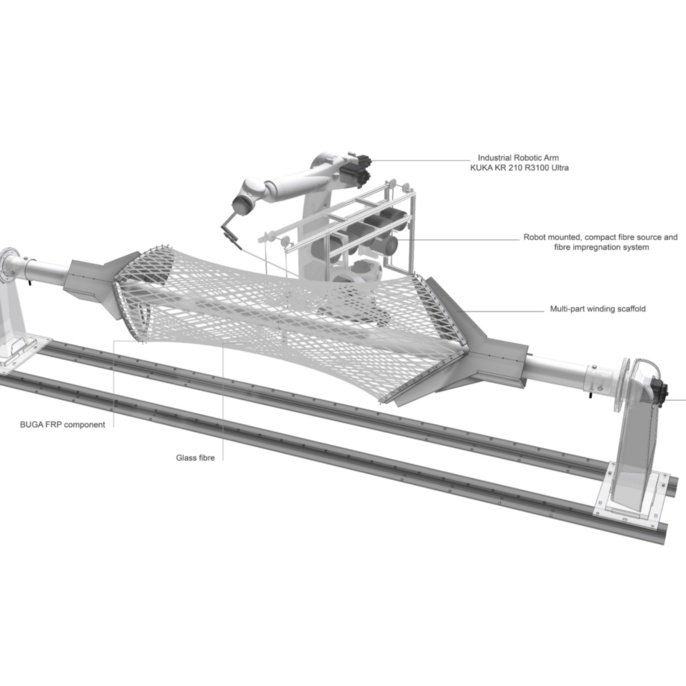

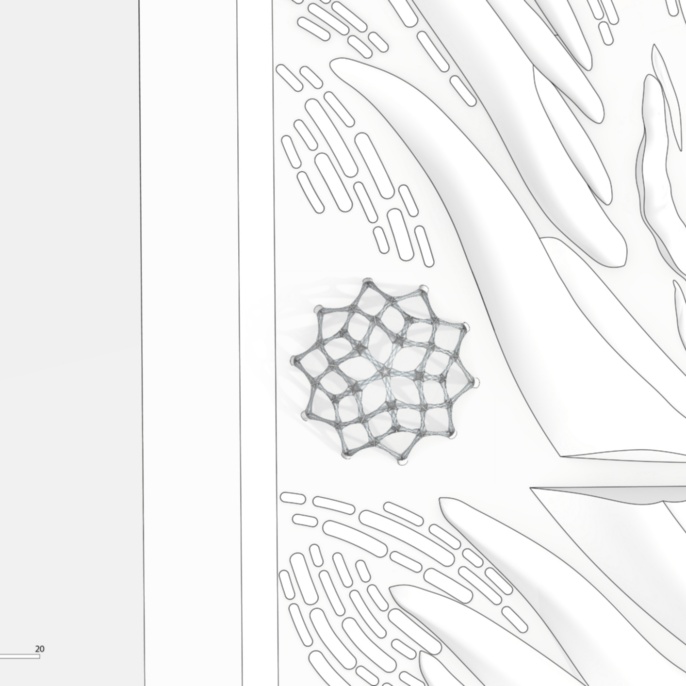

The building components are produced by robotic, coreless filament winding, a novel additive manufacturing approach pioneered and developed at the University of Stuttgart. Fibrous filaments are freely placed between two rotating winding scaffolds by a robot. During this process, the predefined shape of the building component emerges only from the interaction of the filaments, eliminating the need for any mould or core. This allows for bespoke form and individual fibre layup for each component without any economic disadvantage. In addition, there is no production waste or material off-cuts. During manufacturing, a lattice of translucent glass fibres is generated, onto which the black carbon fibres are placed where they are structurally needed. This results in highly load-adapted components with a highly distinct architectural appearance.

Full production took place at the project’s industrial partner FibR GmbH. Each component takes between four to six hours to make from around 1.000 meters of glass fibre and 1.600 meters of carbon fibre on average.

UNIQUE LIGHTWEIGHT STRUCTURE AND EXPRESSIVE ARCHITECTURAL SPACE

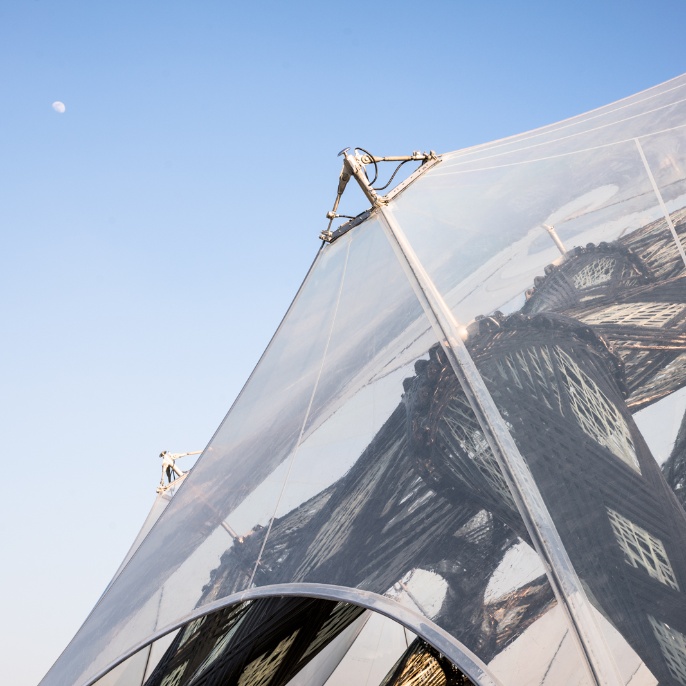

The pavilion covers a floor area of around 400 square meters and achieves a free span of more than 23 meters. It is enclosed by a fully transparent, mechanically pre-stressed ETFE membrane. The primary load bearing structure is made from 60 bespoke fibre composite components only. With 7.6 kilograms per square meter, it is exceptionally lightweight, approximately five times lighter than a more conventional steel structure. Elaborate testing procedures required for full approval showed that a single fibrous component can take up to 250 kilonewtons of compression force, which equals around 25 tons or the weight of more than 15 cars. The pavilion shows how a truly integrative approach to computational design and robotic fabrication enables the development of novel, truly digital fibre composite building systems that are fully compliant with the stringent German building regulations, exceptionally light, structurally efficient and architecturally expressive.

Embedded in the wavelike landscape of the Bundesgartenschau grounds, the pavilion translates the innovation on a technical level into a unique architectural experience. The black carbon filament bundles, wrapping around the translucent glass fibre lattice-like flexed muscles, create a stark contrast in texture that is highlighted by the pavilion’s fully transparent skin. This distinctive architectural articulation is further intensified by the gradient from sparser carbon filaments at the top towards their denser application on the slenderest components that meet the ground. While most visitors may not have seen anything like it before, the pavilion exposes its underlying design principles in an explicable yet expressive way. Its unfamiliar yet authentic architectural articulation evokes new ways of digital making, which no longer remain a futuristic proposition but already have become a tangible reality.

The BUGA Fibre Pavilion is centrally located on the Summer Island of the Bundesgartenschau 2019 and will house the exhibition “Zukunftskarusell”. It will be opened on 17th of April 2019 by the Minister President of the State of Baden-Wuerttemberg.

The research on fibre composite building systems and structures will be further pursued in the context of the new Cluster of Excellence “Integrative Computational Design and Construction for Architecture” at the University of Stuttgart.

PROJECT PARTNERS

ICD – Institute for Computational Design, University of Stuttgart

Prof. Achim Menges, Serban Bodea, Niccolo Dambrosio, Monika Göbel, Christoph Zechmeister

ITKE – Institute of Building Structures and Structural Design, University of Stuttgart

Prof. Jan Knippers, Valentin Koslowski Marta Gil Pérez, Bas Rongen

with support of:

Rasha Alshami, Karen Andrea Antorvaeza Paez, Cornelius Carl, Sophie Collier, Brad Elsbury, James Hayward, Marc Hägele, You-Wen Ji, Ridvan Kahraman, Laura Kiesewetter, Xun Li, Grzegorz Lochnicki, Francesco Milano, Seyed Mobin Moussavi, Marie Razzhivina, Sanoop Sibi, Zi Jie Tan, Naomi Kris Tashiro, Babasola Thomas, Vaia Tsiokou, Sabine Vecvagare, Shu Chuan Yao

FibR GmbH, Stuttgart

Moritz Dörstelmann, Ondrej Kyjanek, Philipp Essers, Philipp Gülke

with support of:

Leonard Balas, Robert Besinger, Elaine Bonavia, Yen-Cheng Lu

Bundesgartenschau Heilbronn 2019 GmbH

Hanspeter Faas, Oliver Toellner

PROJECT BUILDING PERMIT PROCESS

Landesstelle für Bautechnik

Dr. Stefan Brendler, Dipl.-Ing. Steffen Schneider

Proof Engineer

Dipl.-Ing. Achim Bechert, Dipl.-Ing. Florian Roos

DITF German Institutes of Textile and Fiber Research

Prof. Dr.-Ing. Götz T. Gresser, Pascal Mindermann

PLANNING PARTNERS

Belzner Holmes Light-Design, Stuttgart

Dipl.-Ing. Thomas Hollubarsch

BIB Kutz GmbH & Co.KG, Karlsruhe

Dipl.- Ing. Beatrice Gottlöber

Transsolar Climate Engineering, Stuttgart

Prof. Thomas Auer

Frauenhofer-Institut ICT

Dipl.-Ing. Elisa Seiler

FILM PRODUCTION

Photography

Roland Halbe

Camera

swabian studio GmbH

Cut

amplify design GmbH

Music

Soundtaxi GmbH

Contact

Marta Gil Pérez

Dr.-Ing.Research Group Leader I IntCDC

Jan Knippers

Prof. Dr.-Ing.Institute Director